Selecting the Right Crucible for Glass Production

By A Mystery Man Writer

Description

Glass production can be a costly process, and cost savings can be made with the crucibles used, but it is important to select the right crucible.

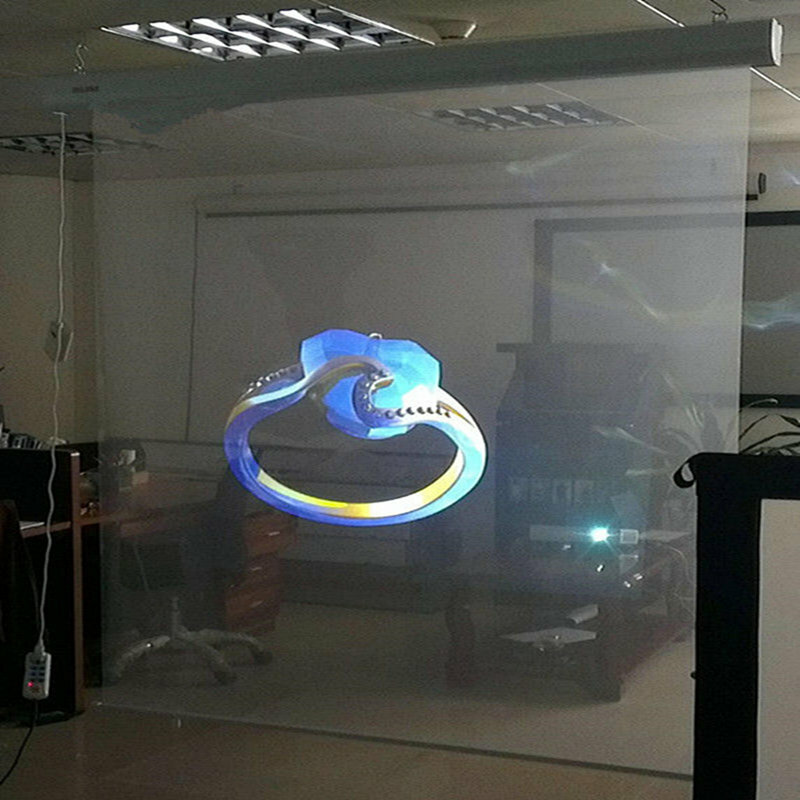

Industrial glass - Glassmaking in the laboratory

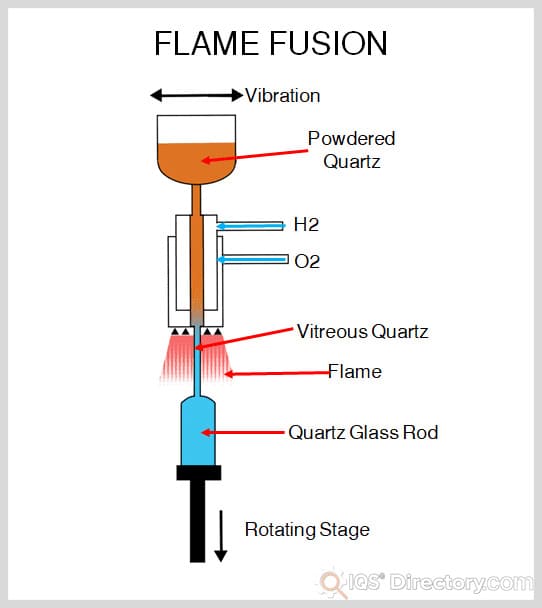

How To Best Prepare Your Crucible for Casting

Technician pours molten glass from a crucible - Stock Image - T830/0097 - Science Photo Library

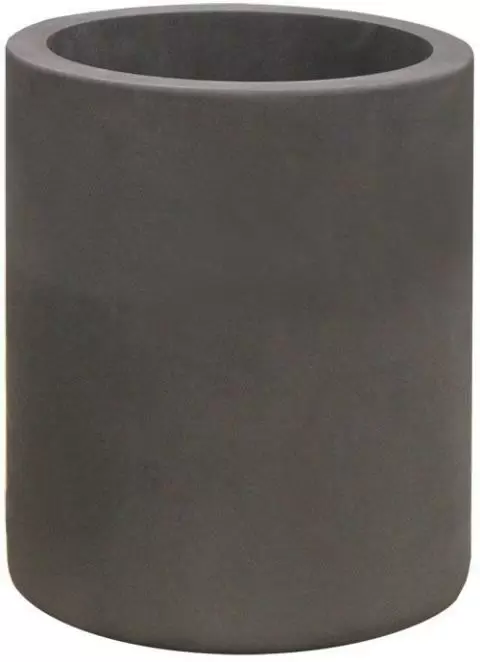

Graphite Crucible: What Is It? How Does It Work? Materials

Made of high quality, heavy duty, Borosilicate 3.3 glass Measures 2.2 tall and 1 in diameter Features sintered disc with G-3 porosity Perfect for

Gooch Crucible, 15ml - Sintered Disc, G-3 Porosity - Borosilicate Glass - Eisco Labs

Glass Casting 101: Kiln Casting Techniques

Graphite Crucible Manufacturers Suppliers

Glass Crucible for Reactive Chemicals

Graphite Crucible for Metal & Casting Up To 44Lb Capacity

from

per adult (price varies by group size)